Tips To Prevent Molybdenum Wire From Being Broken

Tips To Prevent Molybdenum Wire From Being Broken

Blog Article

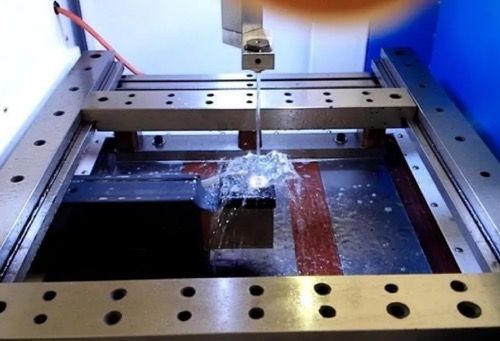

Molybdenum wire is an essential consumable for wire cutting. It is expensive, but it is often broken by the workpiece during processing, which is really a headache! But don’t worry, today I will share a few tips to help you easily avoid the embarrassing situation of molybdenum wire being broken!

1.Use a magnet to suck the workpiece: When cutting halfway, use a magnet to suck the workpiece, which is simple and effective!

2. Fix with a clip: According to the actual processing situation, choose a suitable clip to clamp the workpiece to ensure stability.

3.Programming tips: When programming, hit the lead in the L3 direction to reduce the risk of wire breakage.

4.Cutting of oversized pieces: For large workpieces, you can leave a 0.25MM margin, knock it down with a sledgehammer, cut a large circle or square, and use a file to trim the scar.

5.Program plus D empty back to zero: After cutting to the end, pause , put molybdenum wire in the knife gap, you can put more, so as to effectively prevent the workpiece from falling directly and breaking the molybdenum wire.

As long as you master these little tricks, you can greatly reduce the possibility of molybdenum wire being broken. Of course, there are still many experiences worth learning and exchanging during the processing process. As a molybdenum wire manufacturers, I hope everyone can learn more, exchange with each other, summarize experience, and make progress together!

Keywords:

Report this page